ما الذي تبحث عنه؟

مضخة تروس الرافعة الشوكية! تخيل هذا: أنت تُشغّل رافعة شوكية قوية، وتتنقل ذهابًا وإيابًا في مستودع مزدحم. هل فكرت يومًا في أهمية مضخة تروس الرافعة الشوكية؟ دعني أكشف لك هذا السر الصغير المختبئ في عالم الرافعات الشوكية!

أولاً، دعونا نفهم البناء الأساسي ووظيفة مضخة تروس الرافعة الشوكية.

تعتبر مضخة تروس الرافعة الشوكية مكونًا أساسيًا في النظام الهيدروليكي للرافعة الشوكية تتكون من تروس وغلاف مضخة. من خلال الحركة الدورانية للتروس، تسحب السائل. وظيفتها الرئيسية هي نقل السائل الهيدروليكي من منطقة الضغط المنخفض إلى منطقة الضغط العالي، مما يوفر للرافعة الشوكية قوة هيدروليكية ثابتة لأداء عمليات الرفع. يتيح هذا التصميم نقلًا عالي الكفاءة للطاقة الهيدروليكية، مما يوفر قوة دفع قوية وموثوقية عالية. كما أن الصيانة والعناية الدورية لمضخة تروس الرافعة الشوكية ضرورية للحفاظ على أدائها وعمرها الافتراضي.

دور مضخة التروس

01 التدفق الصامت للطاقة الهيدروليكية

مضخة تروس الرافعة الشوكية هي مكون أساسي في النظام الهيدروليكي. فهي تحوّل الطاقة الميكانيكية إلى طاقة هيدروليكية عن طريق تدوير تروسها، مما يوفر قوة هائلة للرافعة الشوكية. تتميز هذه المضخة بتدفق وضغط وكفاءتها العالية، مما يجعلها موثوقة للغاية في التشغيل. سواءً عند نقل الأحمال الثقيلة أو رفعها إلى ارتفاعات كبيرة، توفر مضخة التروس تدفقًا مستمرًا من الطاقة بصمت، مما يُمكّن الرافعات الشوكية من مواجهة مختلف التحديات بسهولة!

02 التحكم الهيدروليكي السريع والدقيق

بفضل الدوران الدقيق لتروسها، تنقل مضخة تروس الرافعة الشوكية الضغط داخل النظام الهيدروليكي، مما يُمكّن من التشغيل السريع والدقيق. فهي لا تُوفر الطاقة الكافية بسرعة فحسب، بل تُعدّل أيضًا أداء النظام الهيدروليكي بمرونة وفقًا لمتطلبات المُشغّل. سواءً كان رفع البضائع ببطء أو تحريك الرافعة الشوكية بسرعة، فإن مضخة التروس تتكيف تمامًا مع متطلبات العمل المُتنوعة، مما يجعل العمليات أكثر كفاءة وسلاسة!

03 عمر خدمة مستقر وموثوق

تُعد متانة مضخة تروس الرافعة الشوكية ميزةً بارزةً في بيئات العمل الشاقة! فهي مصنوعة عادةً من مواد عالية القوة، وتتحمل ضغط الدوران عالي السرعة لفترات طويلة. علاوةً على ذلك، تمنع أنظمة التشحيم والتبريد الداخلية ارتفاع درجة الحرارة والتآكل أثناء التشغيل لفترات طويلة، مما يُطيل عمرها الافتراضي بشكل كبير. هذا يعني أنه يمكنك الاعتماد على مضخة تروس الرافعة الشوكية بثقة، سواءً في ظروف العمل الشاقة أو المهام طويلة الأمد.

اعتبارات رئيسية عند الشراء

01

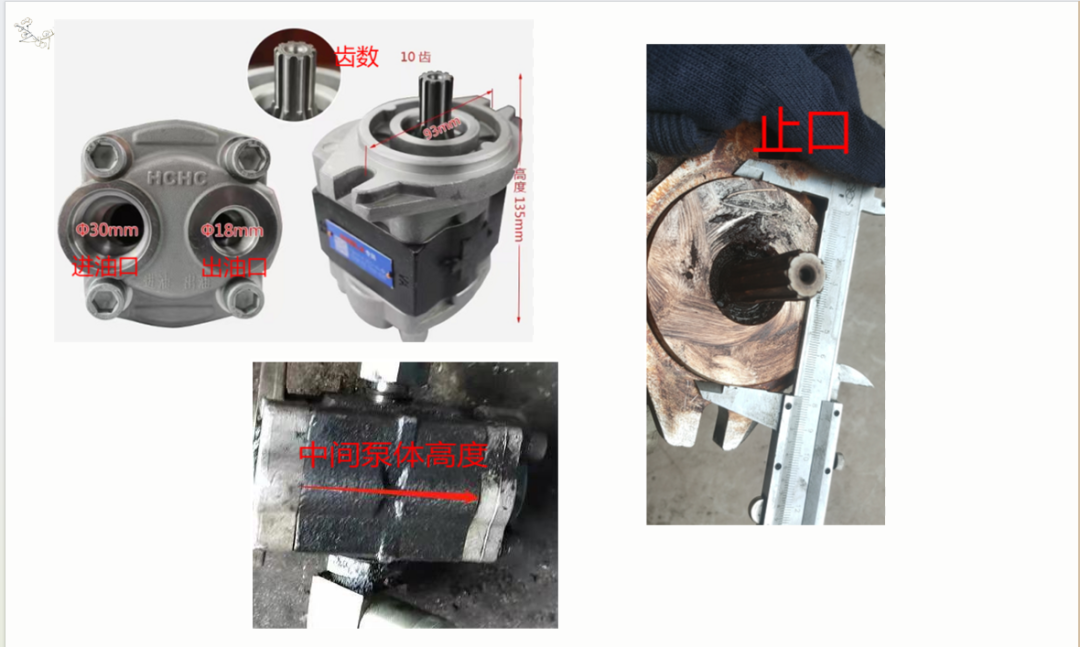

مواصفات المضخة: قم بتقديم سيارتك أو محركك أو طراز المحرك

تأكد من أن مضخة التروس التي تشتريها متوافقة مع طراز رافعتك الشوكية ونظامها الهيدروليكي. اختر دائمًا مضخة تروس تتوافق مع ماركة وطراز رافعتك الشوكية لضمان تركيب سلس وتشغيل موثوق.

02

الجودة والموثوقية

اختر العلامات التجارية والمصنعين ذوي السمعة الطيبة لضمان جودة عالية ومتانة طويلة الأمد. يجب أن تتميز مضخة التروس المتفوقة بعزل ممتاز، وأداء ثابت، وعمر خدمة طويل، مما يضمن تشغيلًا موثوقًا به في ظل الظروف الصعبة.

03

متطلبات الأداء

اختر مضخة تروس تناسب متطلبات تشغيل رافعتك الشوكية. ضع في اعتبارك عوامل مثل وزن الرافعة الشوكية، وقدرتها على الرفع، وبيئة العمل لاختيار مضخة ذات معدل تدفق وضغط مناسبين.

04

الصيانة والدعم

افهم احتياجات صيانة مضخة التروس، وتأكد من أن المورد يقدم خدمات ما بعد البيع والدعم الفني. تأكد من حصولك على خدمات سريعة، مثل الإصلاحات والصيانة وقطع الغيار عند الحاجة.

05

السعر والقيمة مقابل المال

اختر مضخة التروس التي تقدم أفضل قيمة بناءً على ميزانيتك واحتياجاتك. تذكر أن أقل سعر ليس دائمًا المؤشر الأمثل؛ ضع في اعتبارك أيضًا جودة المضخة وأدائها وخدمة ما بعد البيع التي يقدمها المورد.

لجميع احتياجاتك من مضخة تروس الرافعة الشوكية، لا تتردد في الاتصال بنا lifttops.com .

نحن نقدم نصائح دقيقة وإرشادات اختيارية بناءً على طرازك المحدد و متطلبات.

نصائح صيانة مضخة التروس

الصيانة والفحص الدوريان ضروريان لعمر مضخة تروس الرافعة الشوكية وأدائها. من الضروري التأكد من نظافة سائل الهيدروليك وخلوه من فقاعات الهواء وبلوغه اللزوجة المطلوبة. هذا يساعد على تقليل تآكل المضخة ومنع الاحتقان. بالإضافة إلى ذلك، افحص أختام المضخة بانتظام بحثًا عن أي تسريبات لضمان إحكام نظام السوائل.

01. إصلاح جسم المضخة

يحدث تآكل جسم المضخة عادةً في حجرة الشفط. في بعض تصاميم المضخات، يمكن استخدام "طريقة الدوران" للإصلاح. تتضمن هذه الطريقة تدوير جسم المضخة 180 درجة حول محورها، مما يحول حجرة الشفط المتآكلة إلى حجرة ضغط لاستعادة وظيفتها.

02. إطار محمل تروس الرافعة الشوكية

إذا كان السطح النهائي لإطار المحمل متآكلًا أو مخدوشًا، يُمكن طحن جميع إطارات المحامل الأربعة باستخدام آلة تجليخ دقيقة. باستخدام سطح التلامس غير المُسنّن كمرجع، يتم طحن الأسطح النهائية في عملية واحدة.

03. تروس المضخة هي عمال في اتجاه واحد

بما أن التروس تعمل في اتجاه واحد، يحدث التآكل على جانب واحد فقط من الأسنان. يمكن إزالة التآكل الطفيف والنتوءات باستخدام حجر الزيت. غالبًا ما يُسهم عكس اتجاه تعشيق الترس في استعادة أداء المضخة.

04. تآكل وجه جانب الترس (التسجيل الخفيف)

يمكن إزالة الخدوش الطفيفة على جوانب التروس باللَفّ. في حالة التآكل الشديد، يمكن صقل الجوانب بشكل مسطح باستخدام آلة صقل سطحية. ملاحظة هامة: في حال صقل أحد التروس، يجب صقل الآخر أيضًا للحفاظ على فرق سمك أقل من 0.005 مم. تأكد من دقة عالية بين سطح الصقل، والتجويف، والجانب الآخر. بعد الصقل، استخدم حجرًا زيتيًا لإزالة الحواف الحادة والنتوءات، ولكن تجنب شطف الحواف.

05. تآكل التجويف

عادةً ما يكون تجويف الأسطوانة أقل عرضة للتآكل. في حال كان التآكل كبيرًا، يُمكن صقله أو تجليخه ليصبح أكبر حجمًا، ويمكن اختيار محامل أسطوانية أكبر حجمًا لتتناسب معه.

06. ارتداء الجسم والوجه (بعد طحن التروس)

عندما يتم طحن الوجه الخلفي لجسم المضخة للحفاظ على الخلوص المحوري الصحيح بعد طحن التروس، فيجب تشكيله إلى سمك مناسب.

07. تآكل القطر الخارجي للترس والتسجيل

يؤدي التآكل أو الخدش في القطر الخارجي للترس إلى زيادة الخلوص الشعاعي. إذا كان طفيفًا، فقد لا يؤثر بشكل كبير على التشغيل، وغالبًا ما يُترك دون إصلاح. أما إذا كان شديدًا، فيجب استبدال التروس.

08. إصلاح بديل: تركيب غلاف برونزي

بالنسبة لأجسام المضخة حيث لا يمكن تطبيق طريقة الدوران، فإن تركيب غلاف برونزي يمكن أن يعيد التجويف بشكل فعال.

09. تلميع الألواح الجانبية/البطانات العائمة

إذا كانت الألواح الجانبية أو البطانات العائمة محوريًا مهترئة أو مخدوشة أو محززة، فقم بتلميع السطح التالف. ضع معجون التلميع رقم 400-600 على سطح مستوٍ (مثل قطعة من الزجاج المسطح)، ثم أضف الكيروسين أو المذيب، ثم أدر المكون برفق على المعجون لتلميعه.

أخيرًا، استبدل قطع مضخة التروس في أسرع وقت ممكن حسب تكرار الاستخدام وظروف التشغيل لضمان عملها بكفاءة عالية. لا يمكن للنظام الهيدروليكي لرافعتك الشوكية الحفاظ على أعلى مستويات الكفاءة والإنتاجية إلا من خلال الصيانة العلمية والفعالة.

تذكير هام: لا تفكّ مضخة التروس بتهور. تقنيات الإصلاح الصحيحة ضرورية، وتهدف هذه المقالة إلى تقديم مساعدة قيّمة لفنيي الصيانة.

خاتمة:

بعد رؤى اليوم، هل لديك الآن فهم متجدد لمضخة التروس الخاصة بالرافعة الشوكية؟ باعتباره المكون الأساسي للنظام الهيدروليكي للرافعة الشوكية، فهو يوفر أداءً قويًا وتشغيلًا موثوقًا به، ويلعب دورًا لا غنى عنه في وظائف المعدات. تذكر أن تقوم بصيانة مضخة تروس الرافعة الشوكية الخاصة بك بشكل منتظم، وإبقائها في حالة مثالية لضمان تجربة رافعة شوكية أكثر كفاءة وإنتاجية!